Manufacturing Business Addon Module for POS

Rs24,900.00

🏭 Manufacturing Business Module

The Manufacturing Module is designed to help businesses seamlessly manage production, recipes, raw material usage, wastage, and finished goods within the POS system. Whether you’re manufacturing products from scratch or repackaging raw materials into sellable quantities, this module ensures accuracy, efficiency, and profitability tracking.

👉 The Manufacturing Business Module is the ultimate tool to plan, control, and optimize your production processes, ensuring accurate cost tracking, recipe management, and smooth integration with POS System.

Navigate to Recipes → Go to Manufacturing → Recipes. Add New Recipe → Choose the final product and define ingredients. Set Wastage % → For raw materials and final output. Enter Production Details → Define output quantity and instructions. Save & Produce → Generate production batches, track costs, and manage stock. Sell via POS → Finished products are instantly available for sale. Food Manufacturing: Bakeries, sweet shops, packaged foods. Beverage & Oil Repackaging: Cooking oil, bottled water, juices. Household Goods: Detergents, soaps, cleaning items. Textile & Apparel Production: Raw fabric → finished clothes. Pharmaceuticals & Cosmetics: Mixing ingredients for creams, tablets, or lotions.

🛠 How It Works

✅ Use Cases

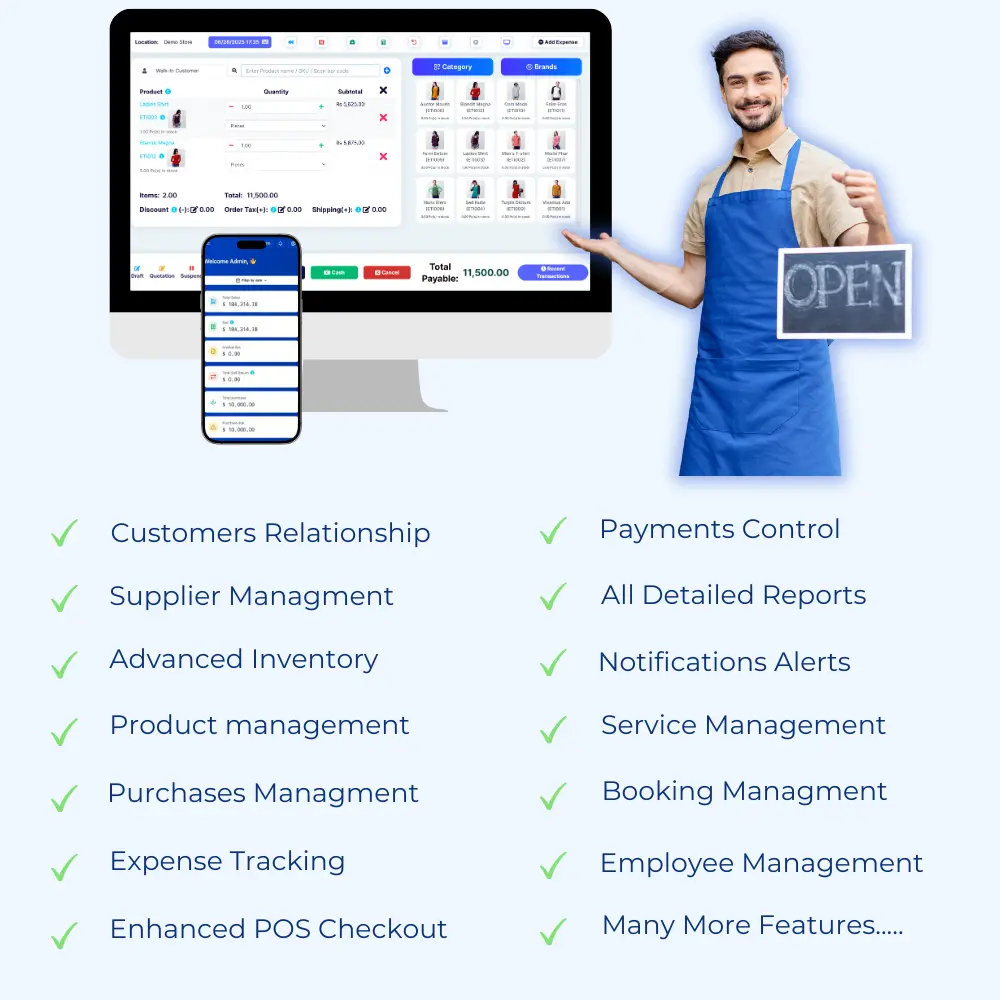

✅ Advance Inventory

✅ Customer Relationship

✅ Supplier Management

✅ Product management

✅ Purchases Management

✅ Expense Tracking

✅ Payments Control

✅ All Detailed Reports

✅ Notifications Alerts

✅ Service Management

✅ Booking Management

✅ Employee Management

✅ Enhanced POS Checkout

✅ Many More Features…..

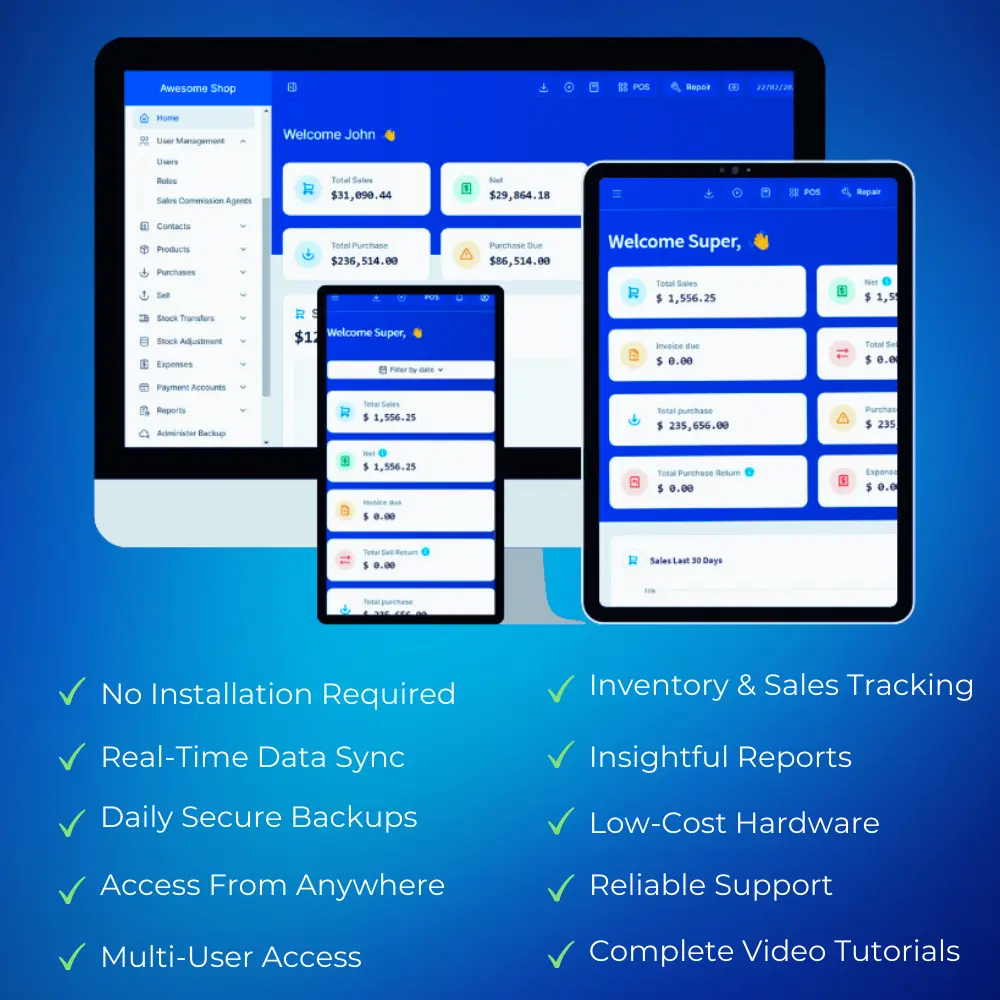

🛠️ No Installation Required

📊 Real-Time Data Sync

☁️ Daily Secure Backups

📈 Insightful Reports

🌐 Access From Anywhere

👥 Multi-User Access

📦 Inventory & Sales Tracking

📞 Reliable Support

💰 Low-Cost Hardware Friendly

🎥 Complete Video Tutorials

- 100% Genuine Lifetime License

- Dedicated Domain & Hosting

- Reliable Support & Video Tutorial

Please Click Here to use our pricing calculator to choose a suitable option, or click the Join Now Button below to see our full pricing details

Join Now

🏭 Manufacturing Business Module

The Manufacturing Module is designed to help businesses seamlessly manage production, recipes, raw material usage, wastage, and finished goods within the POS system. Whether you’re manufacturing products from scratch or repackaging raw materials into sellable quantities, this module ensures accuracy, efficiency, and profitability tracking.

🔑 Key Features & Functionalities

📋 Recipe Management

-

Create and manage recipes for each product you manufacture.

-

Define exact ingredients, raw materials, and instructions.

📦 Ingredient & Raw Material Tracking

-

Use raw materials from your product list.

-

Mark certain products as “Not For Sale” if they’re only used internally for production.

♻️ Wastage Percentage

-

Define wastage at two levels:

-

Ingredient wastage (e.g., cleaning vegetables, trimming materials).

-

Final product wastage (due to quality issues or damage).

-

💰 Production Cost Calculation

-

Get an accurate cost of production per batch.

-

Selling price is calculated based on manufacturing cost + margin, not purchase price.

📝 Production Instructions

-

Add detailed steps for manufacturing to ensure consistent processes.

📑 Copying Recipes

-

Save time by duplicating an existing recipe and adjusting ingredients as needed.

🔄 Repackaging & Selling

-

Ideal for businesses that purchase raw goods in bulk (e.g., oil, rice, flour) and repackage them into smaller retail sizes.

-

Example: Purchase oil in tons/liters, then create recipes for 1L, 500ml, and 250ml packs.

📊 Profit Calculation

-

Profit is based on manufacturing cost, not purchase price.

-

Ensures accurate margins and a better pricing strategy.

Manufacturing has 2 main steps:

- Recipe: A Recipe specifies the raw material or ingredients in exact proportions that should be used for manufacturing the final product. For manufacturing a product, standard instructions are followed where ingredients or raw materials are processed in exact quantities to have a quality final product.

- Production: Based on the recipe added for products, in production it shows the total quantity of all raw materials required for the manufacturing of N quantity of product.

There can be further steps like cost calculations, wastage calculations, allocating lot numbers & expiry for the manufactured product.

Cost Calculations:

Cost of the final product depends on Raw material cost, Production cost (labour cost, machinery cost, fuel cost for machines like Petrol/LPG/Electricity) & Wastages. Further, the selling price will have some profit percentage added to this manufacturing cost.Wastage Calculations:

Wastage can be of raw materials or the final manufactured product.

Wastage of raw materials can be like for example, if we take cauliflower, it needs to be cleaned by removing leaves & stems, this goes to the wastage because it’s thrown away and not used.

Manufactured products can sometimes be wasted by leakage or bad quality, or some other unstoppable causes.Lot number:

Generally, most of the manufactured items have a Lot number, which enables tracing of the constituent parts or ingredients, as well as labor and equipment records involved in the manufacturing of the product. This enables manufacturers and other entities to perform quality control checks and issue corrections or recall information to subsets of their production output. It also gives consumers an identifier that they can use in contacting the manufacturer and researching the production of goods received.Expiration Date:

Food products, pharmaceutical products, cosmetics, and many other manufactured products, where the age of the product may impact its safety, have an expiry date added to them. An expiration date or expiry date or best-before, or use-by date is a previously determined date after which the product should no longer be used.

Q1: What is the Manufacturing Business Module in UltimatePOS?

The Manufacturing Module is an add-on designed to help businesses manage recipes, raw materials, wastage, and production processes, ensuring accurate cost and profit tracking for manufactured or repackaged products.

Q2: Can I create and manage recipes for different products?

Yes. You can define recipes with multiple ingredients, specify raw material quantities, and include detailed production steps for each finished product.

Q3: How does the module handle raw materials?

Raw materials are added from your product list. You can also mark them as “Not For Sale” if they are only used internally for manufacturing.

Q4: Can I track wastage during production?

Yes. You can set wastage percentages for raw ingredients (e.g., trimming, cleaning) and for final products (e.g., defective units). This ensures accurate costing and inventory adjustments.

Q5: How is the production cost calculated?

The system calculates the total manufacturing cost based on recipe ingredients, wastage, and other factors. The selling price is then derived from manufacturing cost + profit margin.

Q6: Can I copy an existing recipe for similar products?

Absolutely. You can duplicate an existing recipe and adjust it, which saves time when creating multiple products with similar ingredient structures.

Q7: Is this module suitable for repackaging businesses?

Yes. If you buy in bulk (e.g., oil, rice, flour) and resell in smaller packs, the module helps you repackage efficiently with proper cost and profit tracking.

Q8: How does this module improve profit tracking?

Profit is calculated from the manufacturing cost, not the purchase price. This gives you more accurate insight into profitability for manufactured goods.

Q9: Can I add production instructions for staff?

Yes. You can input detailed step-by-step production instructions to ensure consistent quality and standard operating procedures.

Q10: Who should use the Manufacturing Module?

It’s ideal for food producers, repackaging businesses, small-scale manufacturers, textile/apparel makers, household goods producers, and cosmetic/pharmaceutical businesses.

| Add-On Module | Purchase Individually, Purchase with POS System |

|---|

Reviews

There are no reviews yet.